UNIQUE WORLDCLASS

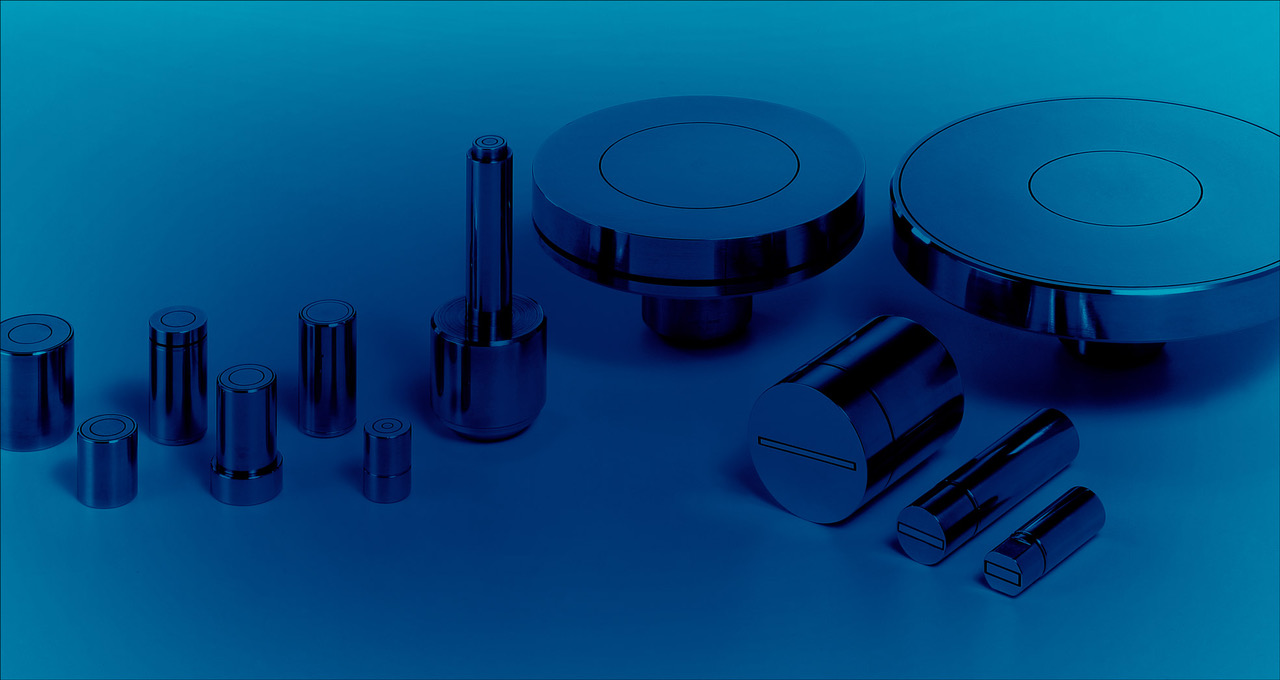

contactless sensor systems

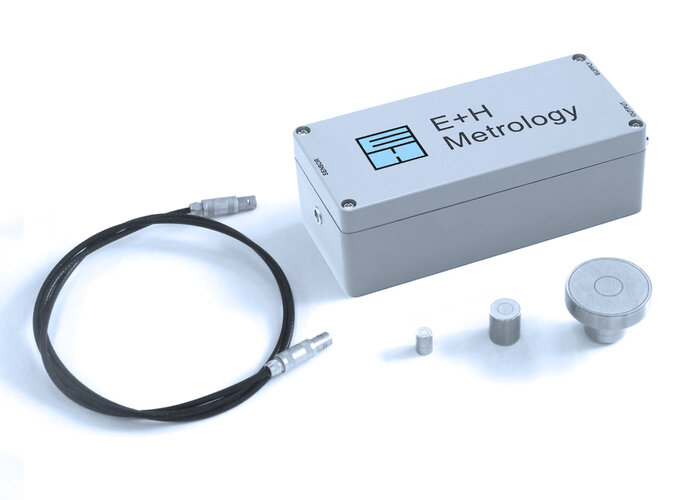

40 years of development make E+H measuring systems what they are today: a sophisticated combination of sensor, cable and distance meter.

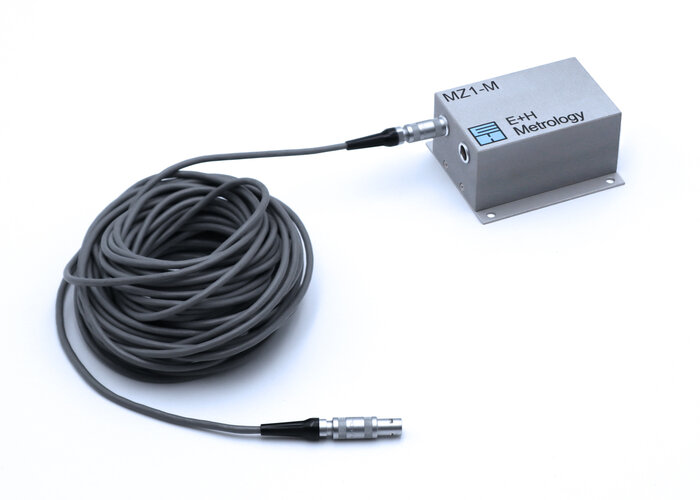

For those who need more than standard: our strength lies in the ability to tailor our systems precisely to your requirements. Challenge us!