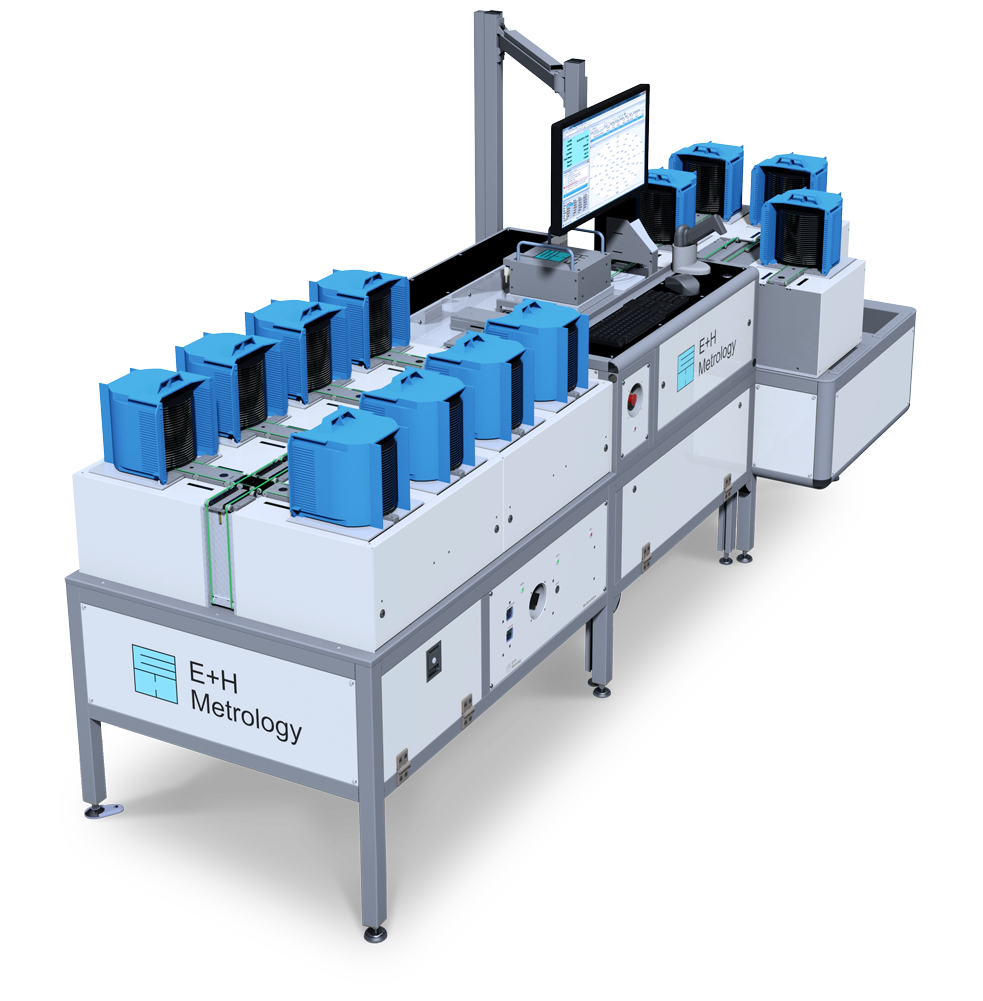

METROLOGY BELT SORTERS

Customization made easy

Whether for incoming and outgoing inspection, quality control in the production process: safety and reliability are always the focus of our modular belt sorter systems. The modules enable specific sorting and measurements with our well proven MX systems, belt transport, receiving stations with wafer switches and much more. More than 35 years of development ensure smooth integration into your production chain - exactly as your process requires.

- Convenient measuring systems for all common wafer characteristics

- Flexible integration of MX 202 modules and individual components

- Long lifetime & low maintenance

- Extremely short production time, individual support

- Many different wafer types and sizes

- Speed: up to 1000 wafers per hour

Scroll down for more

Advantages and features

Our belt sorters also follow a modular design. However, they all have a few unbeatable advantages in common:

- Mature, stable, and safe: Our belt sorters are based on the know-how of many decades and are subject to a continuous process of improvement. In an industrial landscape where process reliability is the most important asset, we offer an unmatched competitive advantage

- High Speed: Time is throughput is cash. With up to 1,000 wafers per hour and extremely reliable measurement results, we help you gain efficiency via production time

- Budget-friendly: All our components require exceptionally low maintenance. With extremely low initial costs at the same time.

- Integratable: Your Belt Sorter system can be seamlessly integrated into your process chain, just as our MX-NT V2 operating software can be integrated into your IT landscape

- Consulting and support: Planning and consulting are part of our DNA - our distributors also provide uncomplicated on-site support for all your questions.

Scroll down for more

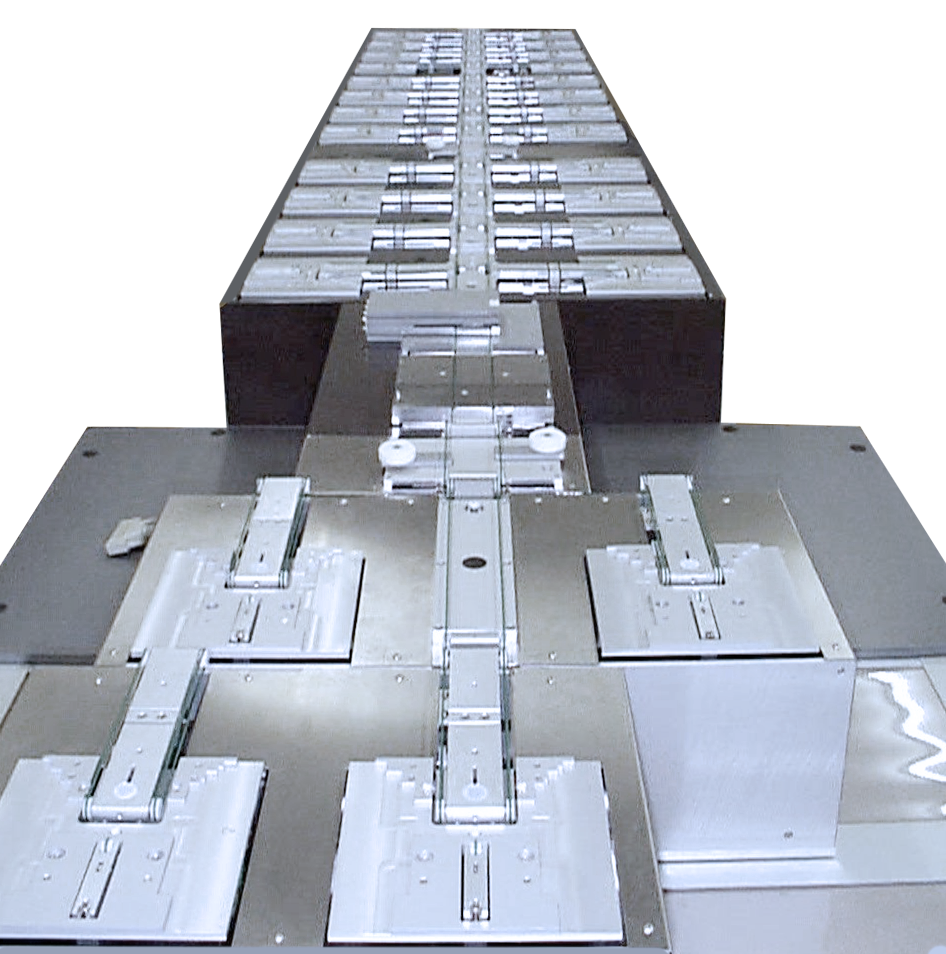

Components & Modules

Our Belt Sorters are used for a wide range of applications. These modules are mainly installed:

- Measuring modules: MX 202 Metrology Modules, AZ6 (6-33) or AZ8 (8-37) geometry module, T-Module with single thickness sensor pair, Resistivity module with integrated optional P/N sensor

- Handling Modules: Sender/receiver lifts, Wafer switches to distribute Wafers in receiver area, movable units with mounted lifts, pass through stations

- Software: All our MX tool series use one and the same Windows operating software MX-NT V2. It combines more than 20 years expericence in Semiconductor requirements.

Sorting by any gained characteristic, such as grouping by thickness, can be done by highly flexible and reusable recipes.

All data can be stored in a MS SQL Server data base or alternatively also into MS Access data bases.

Powerful software options such as a SECS/GEM automation interface or our similar proprietary Simple Soap Server One (S³O) interface allow seamless integration of E+H tools into your production plant.

Scroll down for more

WHICH TOOL

fits my needs?

You have questions, wishes or an order?

We will be happy to consult you personally.

Scroll down for more