OPERATING SOFTWARE

made to measure

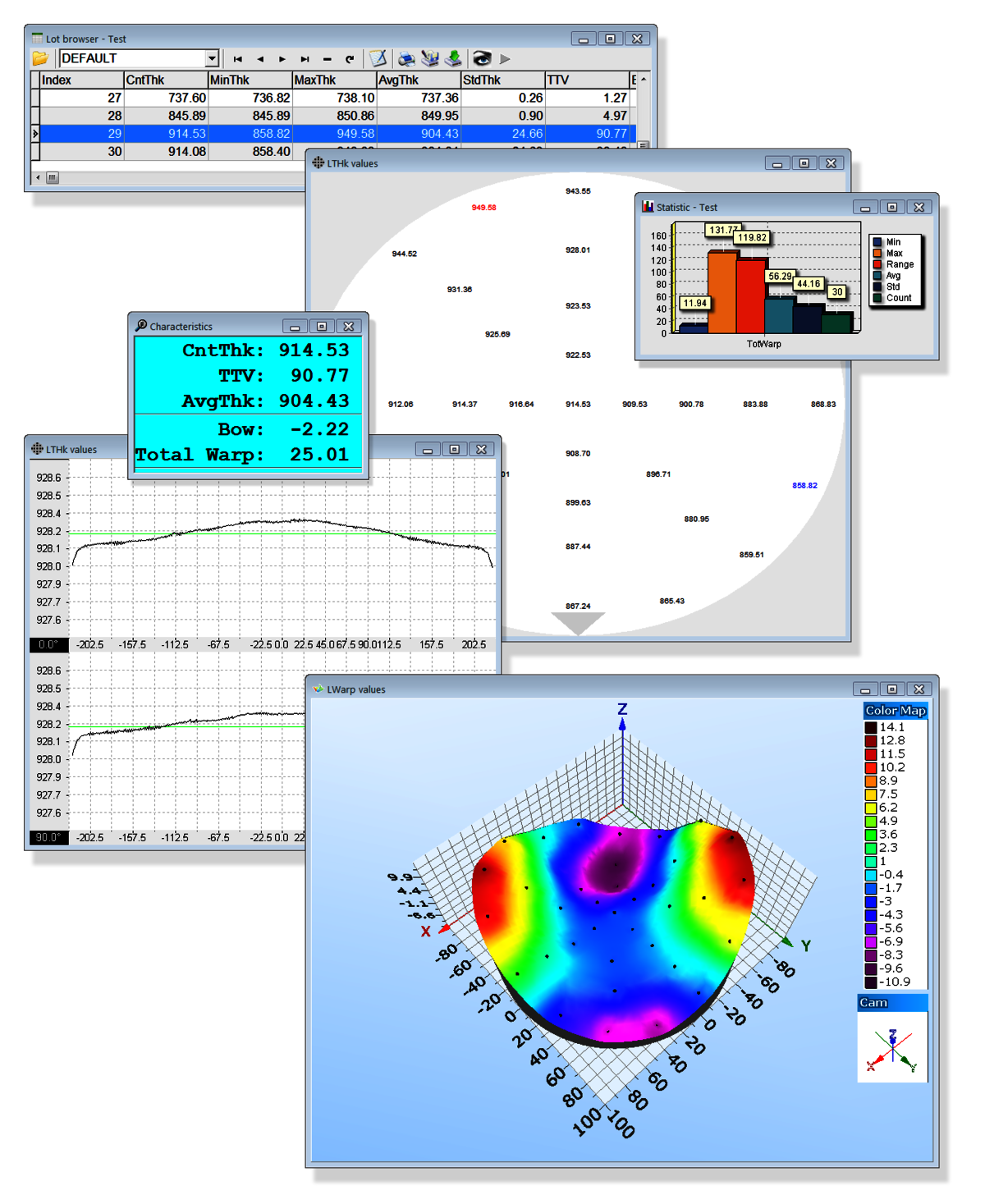

Making your measurement data visible: Our MX-NT V2 operating software supports all measuring systems with the exception of smaller tools that can be operated without a PC. These systems can also be optionally connected to a PC via EHMaster. Our operating system ensures smooth performance at highest performance.

- Highly customizable for engineers

- Intuitive usability for operators

- Extremely powerful and stable

- Continuously developed inhouse for more than 24 years

- Fast support

- Data Storage in powerful SQL-servers and SEMI, SECS/GEM automation

MX-NT V2

The heart of your data

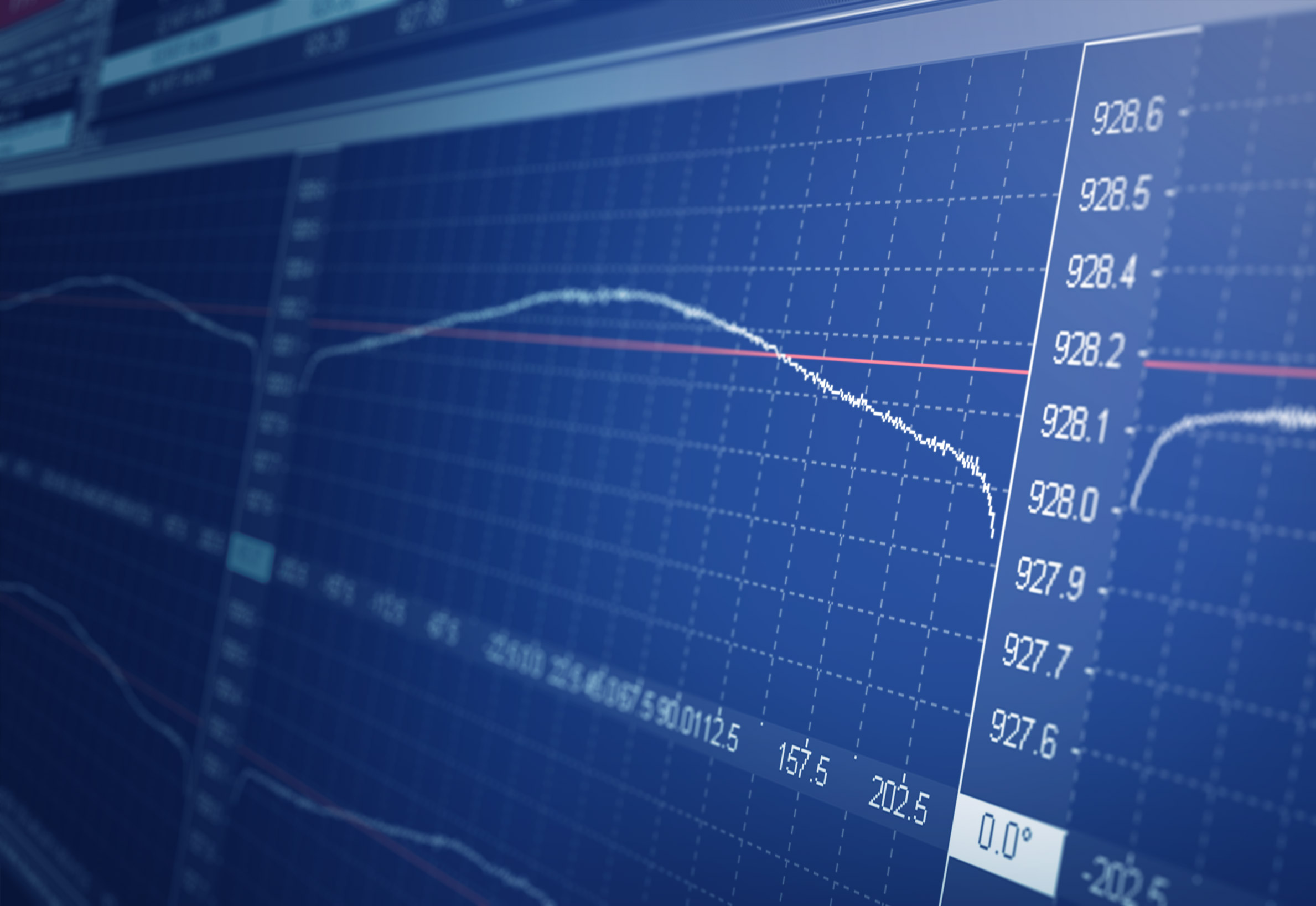

Your measurement data is the heart of your process chain. The MX-NT V2 operating software is not only used to control your measuring system, for data acquisition, evaluation and maintenance. The scope of functions also includes:

-

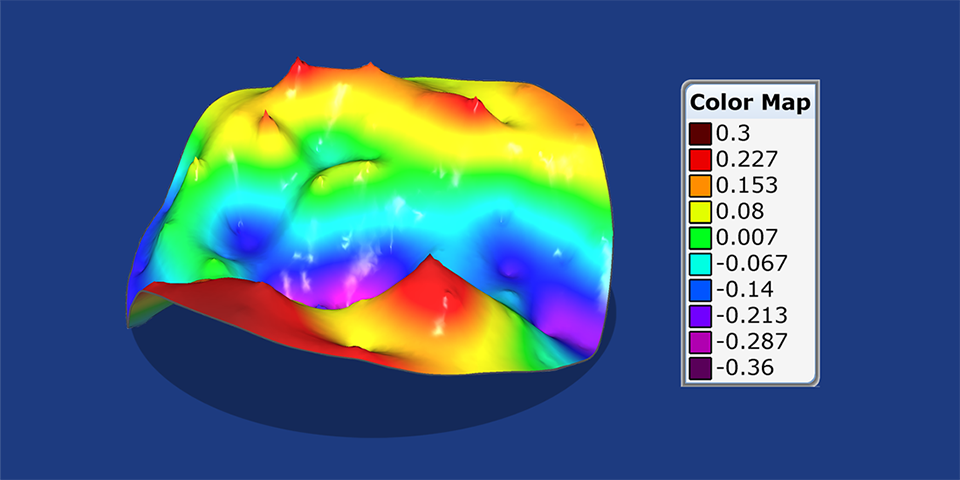

Characteristics: According to your requirements, all common characteristics are calculated according to the measurement modules used (e.g. TTV, FPD, stress, RRV, etc.) and can be read intuitively

-

Workflows: Highly flexible workflow design based on your presets, where any setting can also be entered by the user or transferred from a host

-

Visualization: Customizable interface with many different ways to display your data

-

Data storage: Customized structured storage of measurement data in MS SQL Server or MS Access database engines

-

Customization: Sophisticated special functions allow your engineering team to customize the system to your specific process requirements

-

Automation interfaces: Our software offers easy connectivity for SECS/GEM, S³O (Simple Soap Server One) and IPC

EH-MASTER

The lean solution

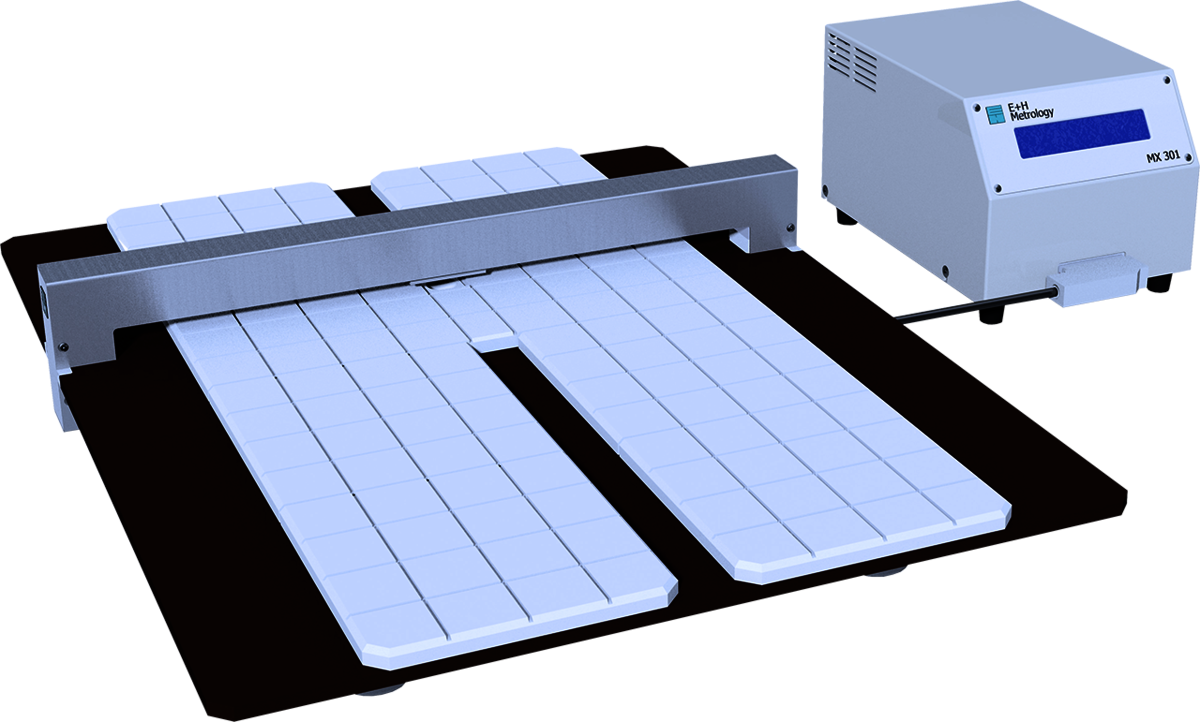

The maintenance and operating software for our smaller systems. E+H Master enables PC operation of our smaller tools and at the same time serves as a maintenance module for troubleshooting in our MC-NT-V2 operating software.

These measuring tools can be controlled with EH-Master: MX 152/153, MX 30 series, MX 601, MX 604

Our MX-30 series, and many other products, can be conveniently controlled via EH-Master.

CUSTOMER TESTIMONIALS

“There are always new features in the software and of course regular updates. Their support is first class.”

Customer · From: E+H customer & partner survey 2021

WHICH SOFTWARE

fits my needs?

You have questions, wishes or an order?

We will be happy to consult you personally.